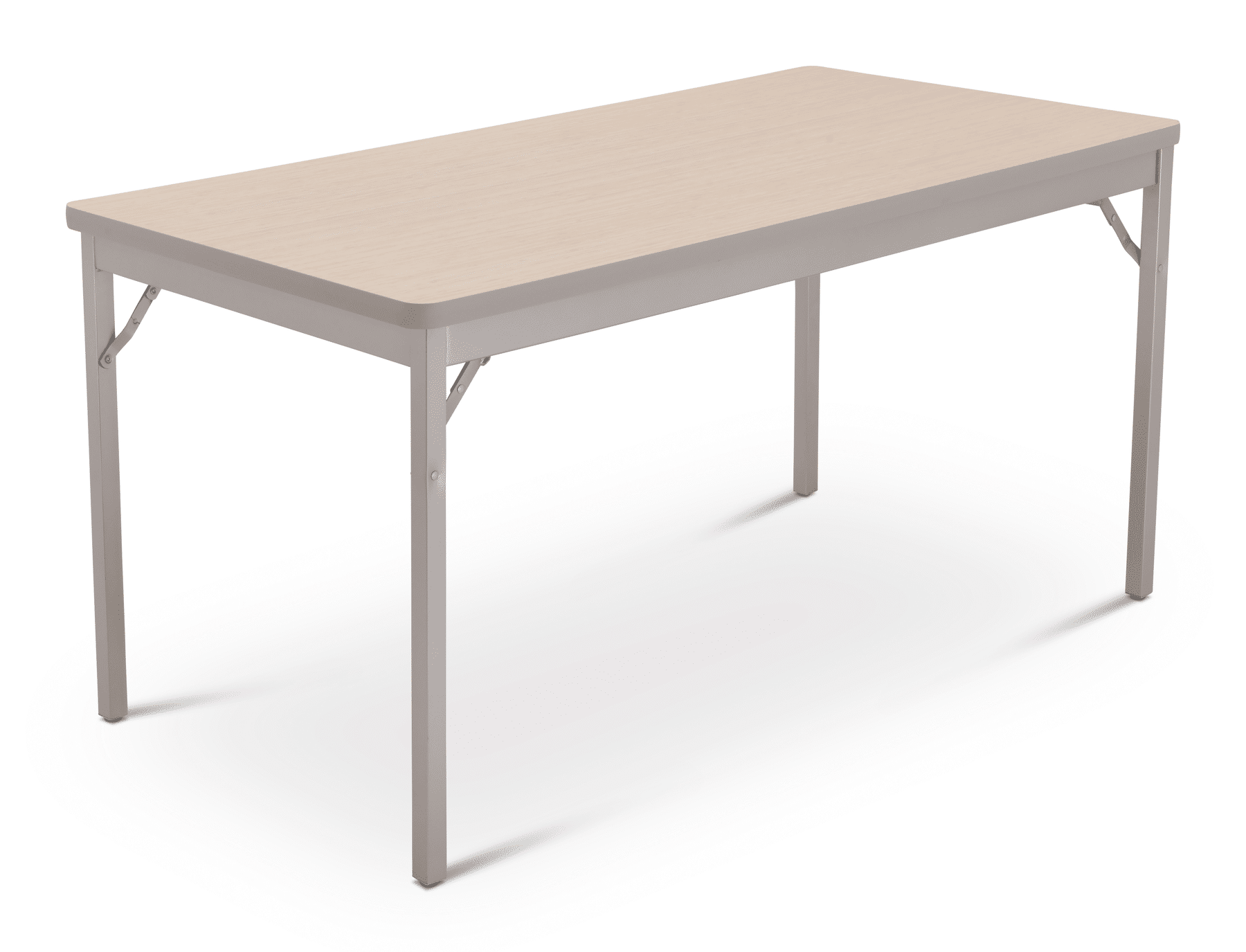

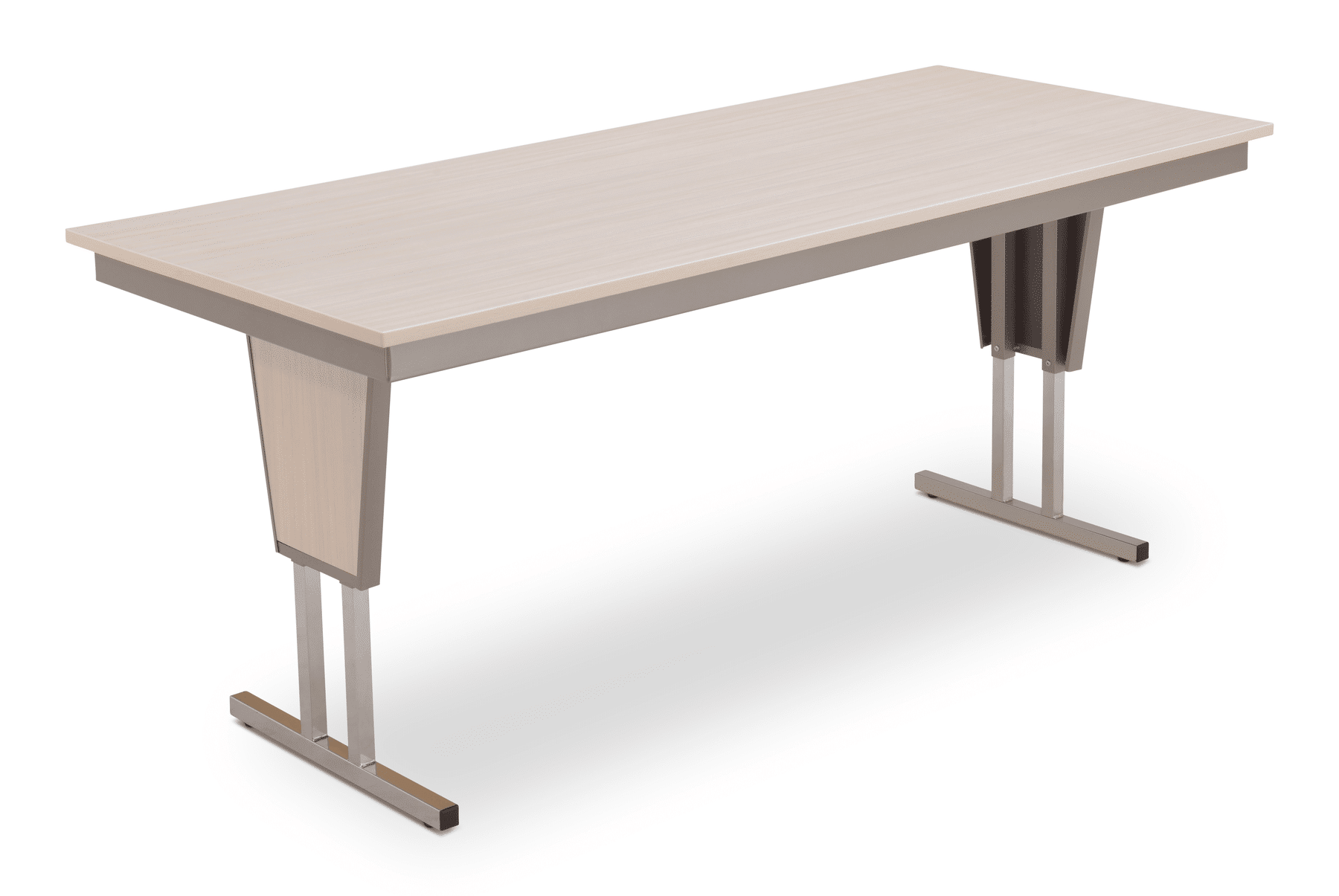

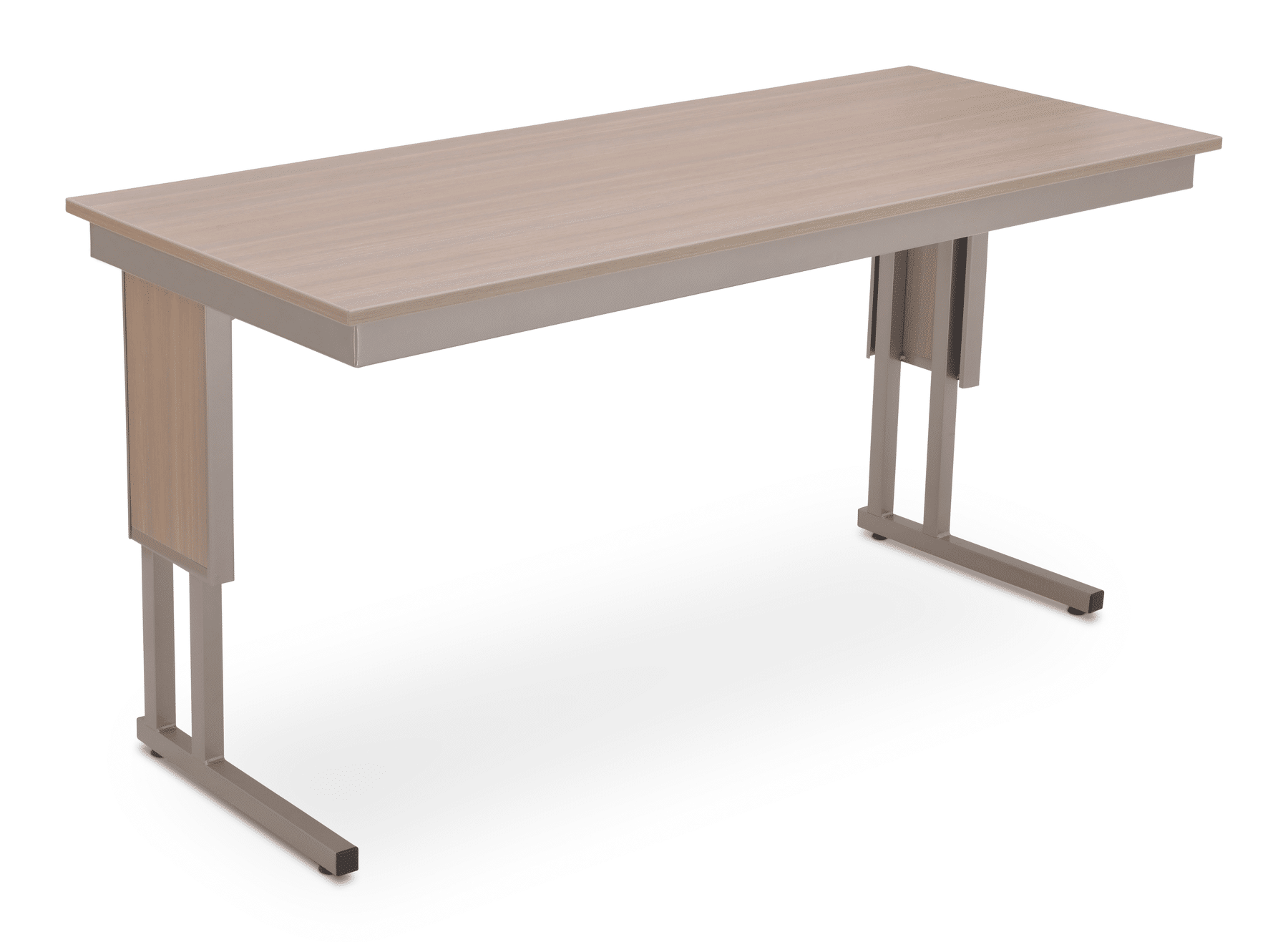

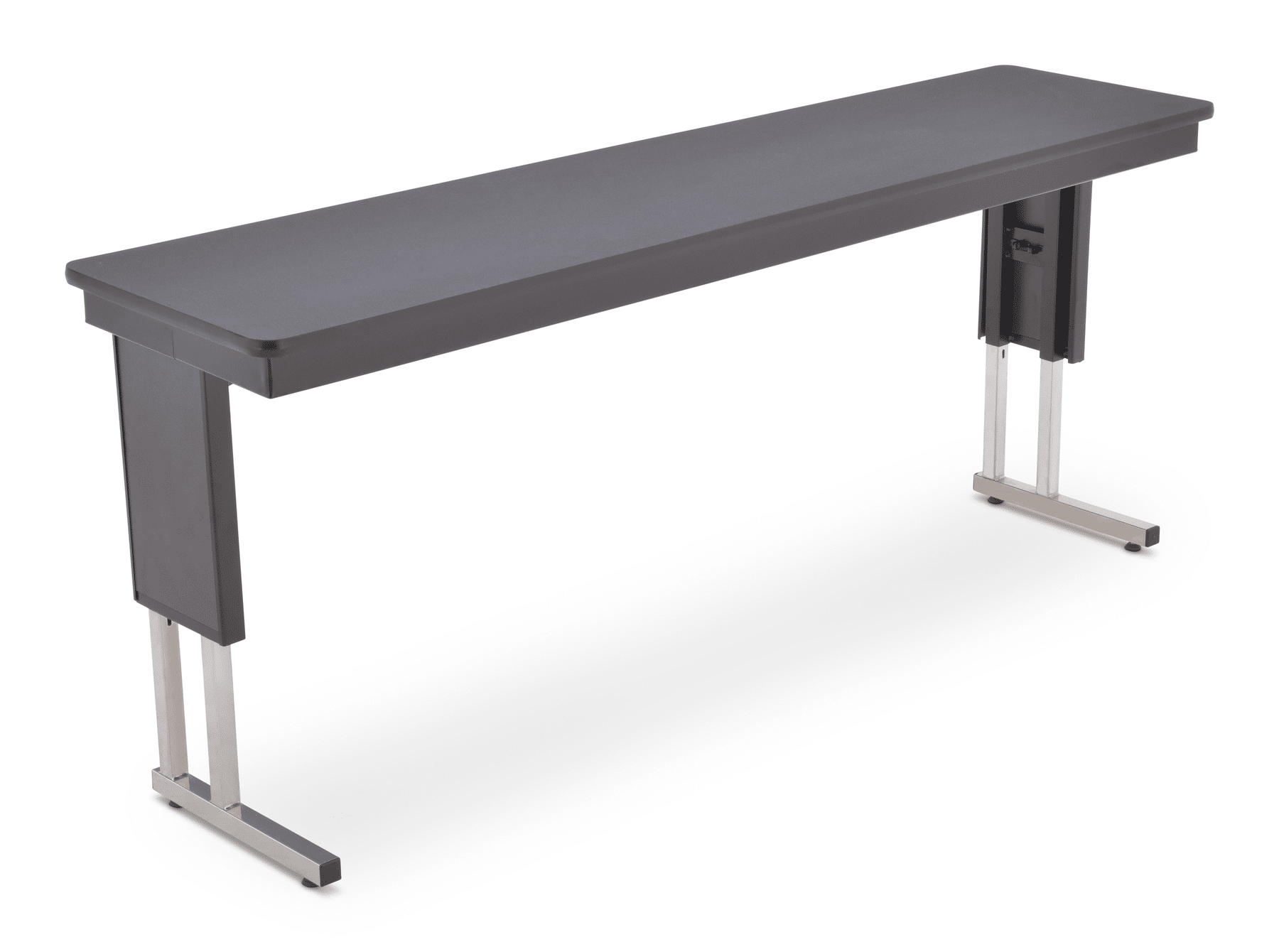

Regency Folding Painted Series

Call for Price

Rectangle Folding Table

- Designed for more demanding environments

- Integrated frame constructed by welding legs to apron

- Painted legs standard, folds in pairs

- Fully assembled- Just unfold for use

- 1 ¼” top particleboard core available in HPL laminates

- Customizable finishes

Product Details

Customize Barricks’ fully assembled, Regency Folding Painted table to meet your needs. Regency Folding Painted table top is 1 1/8” particleboard core with high pressure laminate (HPL) top surface and moisture resistant bottom surface with a protective T-mold edge or upgraded 3mm edge. The Regency Folding Painted table legs and apron are integrated into a single frame component. Legs are 1 1/4” sq 18 gauge steel welded to apron and 1” x 2” 18 gauge steel cross bar connecting to adjacent leg reinforcing leg stability. Legs have painted finish. Positioning of leg accommodates end seating. Adjustable levelers ensure proper positioning and alignment on uneven floors. Barricks stocks 30 HPL options to create your customized design.

Regency Folding Painted Series- 30″ Height

HPL Top Particleboard Core

| Size | T-Mold Model # | 3mm Model # | Weight |

| 18×72 | RP-1872-PT | RP-1872-PM | TBD |

| 20×60 | RP-2060-PT | RP-2060-PM | TBD |

| 24×60 | RP-2460-PT | RP-2460-PM | TBD |

| 24×72 | RP-2472-PT | RP-2472-PM | TBD |

| 30×60 | RP-3060-PT | RP-3060-PM | TBD |

| 30×72 | RP-3072-PT | RP-3072-PM | TBD |

| 36×72 | RP-3672-PT | RP-3672-PM | TBD |

Specification & Materials

Top:

HPL Particle Board Core- 1 1/8″ particleboard core with high pressure laminate (HPL) top surface, moisture resistant backer bottom surface finished with a protective edge option- t-mold or 3mm.

Edging:

T-mold- an extruded plastic edging in the shape of a “T”. The stem part is barbed and inserted into a slot in the core board. The friction barbs prevent the t-mold from coming out of the core. T-mold external surface is slightly rounded and provides protection against impacts to side. T-mold is an economical edge.

3mm- an extruded 3mm (1/8”) plastic that is machine glued to panel sides sealing edge, then machine trimmed to fit panel thickness. Edging provides protection against impact to sides. 3mm corners are square and more expensive than using T-mold.

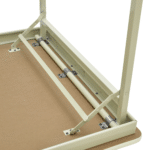

Frame:

Table legs and apron are integrated (welded) into a single frame component.

Apron uses strong, rigid 2 1/4″ 18 gauge steel with rolled bottom edge for added strength attached with coarse, deep threaded screws designed specifically for particleboard and plywood.

Legs are 1 1/4″ sq 18 gauge steel welded to apron are also welded to 1″ x 2″ 18 gauge steel cross bar connecting to adjacent leg. This design combination significantly reinforces leg stability. Legs are secured in open position with compression lock on each leg. Leg positioning easily accommodates end seating. Adjustable levelers ensure proper height positioning/alignment on uneven floors.

Assembly

No assembly required for this table. Just remove from box, unfold legs, and use.